How Distilling Works

We use high-tech equipment to make our whiskey but still rely on the same laws of fractional distillation—a difference in boiling points that allows us to separate ethanol from water—the same technique that has been used for centuries.

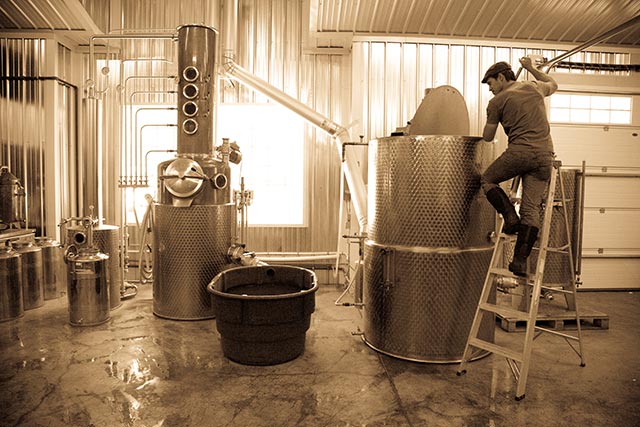

1. Mashing & Fermenting the Grain

We cook 500 lbs of grain in 200 gallons of water in our mash tank to create a sugar and nutrient rich environment ideally suited for yeast to grow. We transfer the cooled mash into one of our blue fermentation tanks and after 3-7 days, the yeast has consumed most of the sugar, turning the mash into a 10-12% ABV “distiller’s beer” or “wash.” A pump moves the wash into the pot of the still.

2. Boiling the Wash

The still is heated gradually (1-2 hours) until the wash just starts to boil. Since alcohol boils at 173 F and water at 212 F, the alcohol starts to boil out of the wash first. For the next 2-3 hours, a mix of alcohol, water and other flavor enhancing components boil out of the wash.

3. Distillation and Reflux

As alcohol and water vapors rise from the pot, they enter the copper column where they “reflux” – the lighter alcohol vapors continue to rise and the water falls back to the pot. The temperature of the column, and degree of reflux, control the quality and flavor of the distillate.

4 & 5. Condensing the Vapors

Vapors that are light enough to pass through the column, travel across the lyne arm and turn back into liquid in the water-cooled condenser.

6. The Distillate

The distillate comes out of the still in phases, starting with the powerfully flavored “heads,” followed by a long phase of “hearts” and finishing with lower proof “tails.” The heart of the run is collected for bottling or aging while the heads and tails are added back to the next distillation run for rework. The art of distillation is deciding where to make the “cut” between heads, hearts and tails. At this point the spirit is flavored only by the grains from the mash and is clear in color. It is often called “white dog” or “new make” but we call it “Glacier Dew.”

7. Barrel Aging

Only once the new make spirit ages in oak barrels, does it takes on an amber color and an additional layer of flavor from the charred wood. Whether you use new or used, toasted or charred, American or French oak barrels depends on the style of whiskey you are making. Bourbon, for example is aged in new charred American oak barrels while Scotch may be aged in a used French oak sherry cask. Our North Fork and Bad Rock Rye whiskies are aged in new charred barrels while the Wheatfish Whiskey is aged in used barrels.